Content for comparison

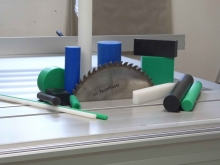

PE1000 - Polyethylene 1000

Construction sliding material with high resistance to abrasion and wear. It has high impact and notch strength without fracture and low friction coefficient. It is hygienic (only for certain colors) and low density - lighter than water. It features a high chemical resistance.

The highest continuous use temperature is 80 degrees Celsius, bearing below freezing point excellently. When limiting use with higher temperature or higher required allowable pressure you may consider using PA6G + oil or PET-GL. When limiting the price you can consider using the PE1000R or PE500, however, the inferior sliding properties of these cheaper materials need to be considered.

- Chain guides.

- Guides for conveyor belts and belts.

- Unloading hoppers and chutes.

- Lateral and lower conveyor lines and conveyed material on lines.

- Sliding and guiding parts of food machines.

- Feeding stars in fillers and labels.

- Can turners.

- Unloading of redler conveyors - bottoms and blades.

- Self-lubricating plain bearings and moldings.

- Very good wear and abrasion resistance

- High impact strength, even at low temperatures

- Excellent chemical resistance

- Low coefficient of friction

- Excellent release properties

- Very low water absorption

- Moderate mechanical strength, stiffness and creep resistance

- Very good electrical insulating and dielectric properties (except static dissipative grades)

- Excellent machinability

- Physiologically inert (several grades are suitable for food contact)

- Good resistance to high energy radiation (gamma- and X-rays)

- Not self-extinguishing

Group of materials Polyethylene:

Engineering plastics and their products can be ordered from TechPlasty. Materials in the same group from different manufacturers are not always directly interchangeable because they may not all have the same technical parameters. Our technical consultants, who have many years of experience in the field of engineering plastics, will be pleased to advise you on the differences in the individual materials, especially in the boundary conditions. Detailed technical data of individual manufacturers' materials can be found in their data sheets.

Some materials trade names are protected trademarks..

TECAFINE® PE 10 is a registered trademark of Ensinger; Nabolen® 1000 is a registered trademark of Indiana Gummi; materiál "S"®, Werkstoff "S"® is a registered trademark of Murtfeldt; Tivar® 1000, Cestilene® HD 1000 is a registered trademark of Quadrant; Polystone® M is a registered trademark of Röchling; Senolen® HD 1000 UHMW is a registered trademark of Senova; ECO-WEAR® 1000 is a registered trademark of SKF;TEKALEN® A6000 is a registered trademark of Terbrack;

All other trademarks or registered trademarks are the property of their respective owners.