Content for comparison

PE1000R - Reprocessed Polyetylene PE1000

This grade, partially composed of reprocessed PE1000 material, has an overall lower property level than the virgin PE1000. PE1000R grade shows a favorable price-performance ratio for applications in many kinds of industries with less demanding requirements.

Customers who place importance on the electrical properties of the material are cautioned that a proportion of PE1000AST can also be used in the production of the black version of this material, i.e. the resulting properties of the black alternative, such as specific internal and specific surface resistance of the material, may be variable and the manufacturer does not guarantee their value.

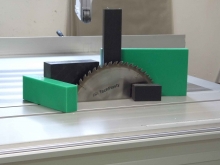

- Wear strips, wear rails, wear guides

- Channels

- Rollers

- Conveyor and conveying equipment

- Lining applications: chutes, hoppers

- Reduces noise

- Self-lubricating

- Chemical-, corrosion- and wear-resistant

- No moisture absorption

- Non-toxic, low-friction surface

Group of materials Polyethylene:

Engineering plastics and their products can be ordered from TechPlasty. Materials in the same group from different manufacturers are not always directly interchangeable because they may not all have the same technical parameters. Our technical consultants, who have many years of experience in the field of engineering plastics, will be pleased to advise you on the differences in the individual materials, especially in the boundary conditions. Detailed technical data of individual manufacturers' materials can be found in their data sheets.

Some materials trade names are protected trademarks.

Materiál "S"® 1000, Werkstoff "S"® 1000 is a registered trademark of Murtfeldt; Tivar® 1000 reclaimed, Cestilene® HD 1000R is a registered trademark of Quadrant; TEKALEN® T 3000 R is a registered trademark of Terbrack;

All other trademarks or registered trademarks are the property of their respective owners.